Did you know? Robot welding can help you to save training time! Here’s how to achieve efficient robot training.

Training welders is a bottleneck for many manufacturers. There is a long-standing shortage of skilled welders in the market and there are not enough trainees to fill the gap. Welding training has been a critical issue for some years.

Robot welding is a great option to reduce the strain on your skilled welders, as we explained in a previous article.

But, it takes time to train your team to use a robot. This can make it hard to get started.

How can you reduce the training time for robot welding? In this article, we introduce some of our best time-saving tips.

How Robot Welding Saves Training Time

There are several advantages of using a robot for welding, including higher productivity, product quality, and efficiency. We explained these advantages in more detail in our article The Simple Way to Flawless Robot Welding. However, robot welding can also help you to save training time.

You see, it takes time to train a skilled welder — between 2 to 8 months. If your business is suffering from a lack of skilled welding candidates, one way is to train up members of your own team. Training helps to overcome the lack of welders in the job market because it means that you don’t have to rely on finding new employees. However, training can be a drain both in terms of time and budget.

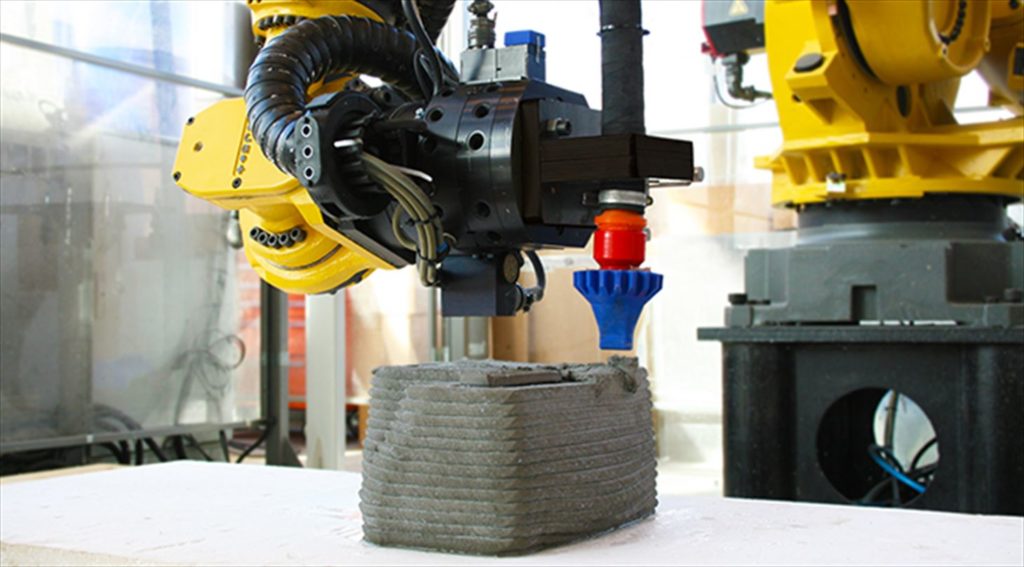

A robot has the potential to reduce this training time. Robot welders can be trained to complete the more routine welds, allowing your skilled welders to focus on more complex welds. This means you don’t have to train as many new welders for those boring, routine welds.

The 2 Ways to Save on Training Time With a Robot Welder

There are two distinct ways that you can reduce training time when deploying your first robot welder. Each requires a slightly different approach:

- Efficiently train your team to operate the robot. This reduces the time it takes to train your employees.

- Use a programming system which makes it easy to program the robot. This reduces the time it takes to “train” the robot for the welding task.

In the next two sections, I’ll tackle each of these individually.

How to Efficiently Train Your Team to Use the Robot

The first time you introduce a robot to a new task, you need to train your team to use the robot. If some members of your team are already experienced with robots this will save some time. However, it’s likely that some members of the team will need to be trained from scratch.

Here are five steps to efficiently train your team in robotics.

Step 1: Pick a Programming Method That’s Easy to Learn

You can drastically reduce the training time by picking the right programming method from the start. Robot programming can be intuitively simple or it can be blindingly complex. A good way to judge a programming system is to watch videos of a robot being programmed for a welding task. If the system looks easy to use, it will probably be easy for your team to learn.

Step 2: Be Clear About the Benefits of the Robot

If your team doesn’t see the benefits of using the robot for welding, they may be resistant to it. Welders on your team may worry that the robot will steal their jobs. Make it clear to everyone that the robot is there to assist your skilled welders, not replace them. Reassure people that nobody will lose their job to the robot. When the team is enthusiastic to learn, training will be more effective.

Step 3: Pick a Clear, Specific Welding Task

Don’t try to do too much too soon. Pick a clear, defined welding task for your first robotic application. Although robots can be used for complex welding operations, you will see more success by selecting a simple task and building your team’s skills gradually by increasing weld complexity for future projects.

Step 4: Aim for Cross Pollination of Skills

The best way to save training time is also a great way to improve training quality: cross-pollination of skills. Get your team to teach your team. This is especially effective with robot welding. The skilled welders on your team will have a lot to teach your robot programmers. Your robot programmers can also teach programming skills to the welders to improve the efficiency of the welding tasks.

Step 5: Have a Training Plan

Planning your training goals is one of the best ways to ensure an efficient training program. A good plan will ensure that you only train your team in the skills which are actually necessary to complete the specific welding task that you decided in Step 3.

How to Save Time When Programming the Robot

You can also save training time by following best practices when programming your welding robot. Efficient programming makes it easier to train your team and ensures that time spent “training” the robot is kept to a minimum.

Here are 5 tips for efficient robot programming.

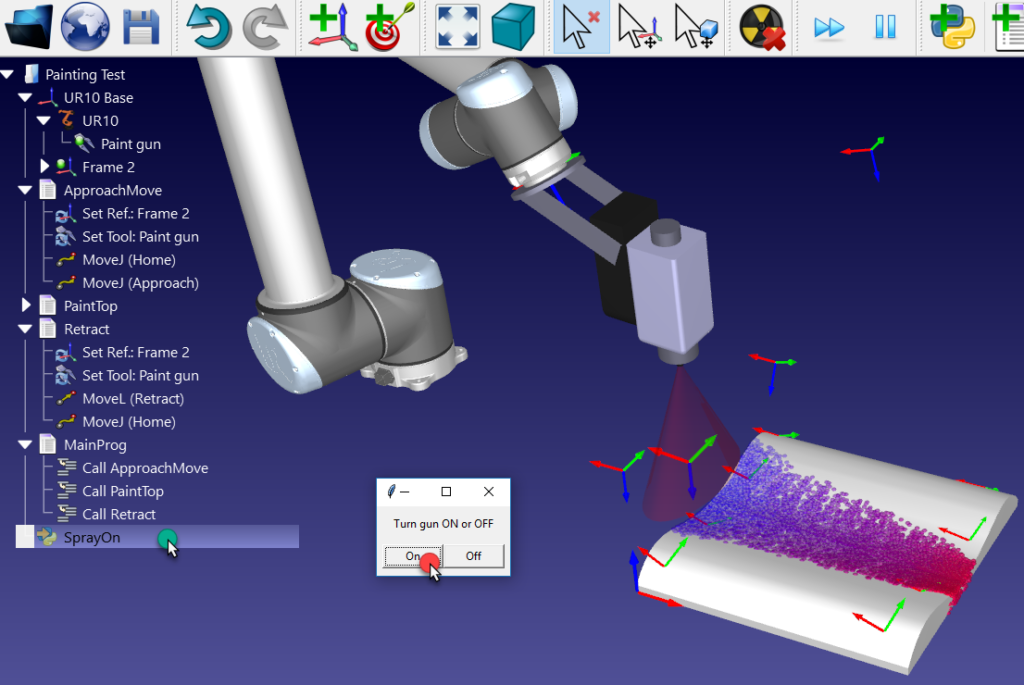

Tip 1: Use Offline Programming

Offline programming is a great way to save programming time. We discussed this in the article 10 Excellent Ways to Save Time With Offline Programming.

Tip 2: Use Programming Wizards

Do you want to know the secret to quick and easy robot programming? Programming wizards! These are specially designed software tools which assist programming of particular tasks, including welding.

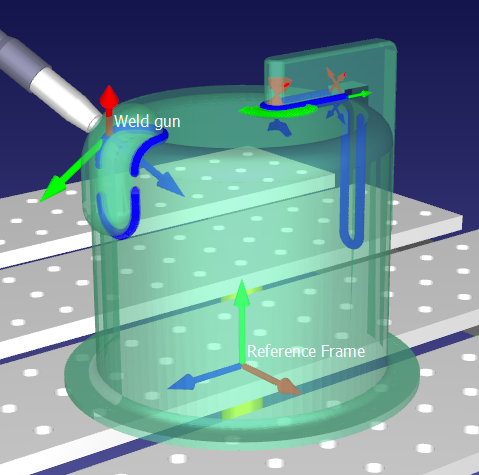

RoboDK has two programming wizards which can be used for welding: The Curve Follow wizard for arc welding and Point Follow wizard for spot welding.

Check out this example video of the Point Follow wizard being used for a spot welding task.

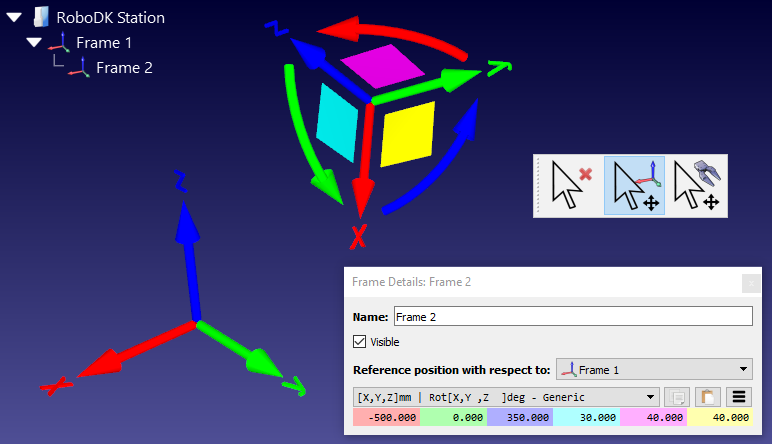

Tip 3: Use Reference Frames

One of the advantages of robots is that they have a large reachable workspace. This means you can move the welding job around the workspace without having to move the robot itself. However, this flexibility can cause problems if you have to reprogram all the robot’s movements every time you change the position of the job.

You can avoid such lengthy reprogramming by associating each welding task with a frame reference. Whenever you want to move the job, you just need to move one single frame instead of every point in the program.

Tip 4: Check Your Reachability

A surefire way to slow down programming is to try to carry out a weld which the robot cannot reach. Make sure all the points of the weld are in the robot’s reachable workspace.

This is simple using RoboDK which provides a graphical representation of the robot’s end effector and allows you to see immediately if the weld falls within the robot’s workspace.

Tip 5: Test the Program

Test, test, test. It really is the best way to ensure your robot programming goes quickly and smoothly. When you thoroughly test your robot program, you will reduce the time it takes to debug.

Robot welding has the potential to really improve your use of the skilled welders on your team. Just make sure that you have a clear training plan, a clear welding task, and you follow our programming tips. That way, you can be sure that your robot training will be efficient and successful!

What concerns do you have about robot welding? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or Instagram.