Manufacturing businesses are continuously seeking innovative solutions to enhance efficiency and productivity. One such groundbreaking technology is RoboDK’s TwinTrack, which allows businesses to easily mimic and replay human movements with robots, streamlining automation processes. This blog delves into the capabilities and benefits of TwinTrack, highlighting its potential to revolutionize manufacturing operations.

What is RoboDK TwinTrack?

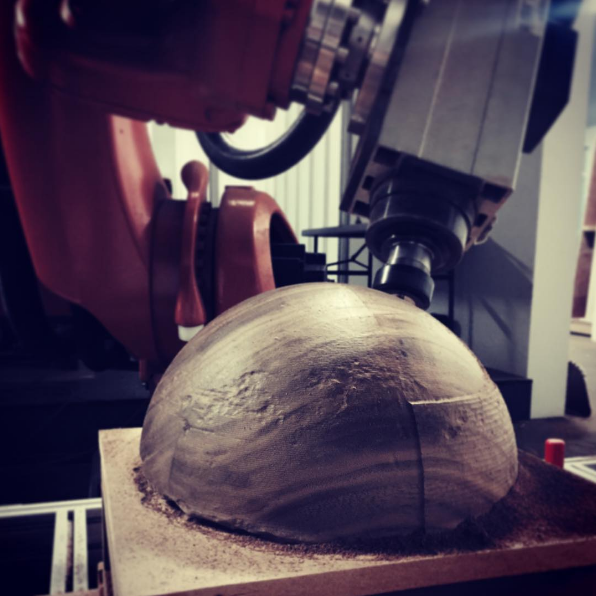

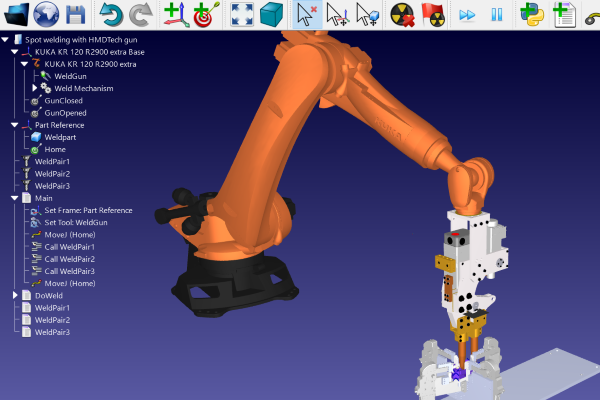

RoboDK TwinTrack is an advanced technology designed to simplify robot programming by enabling a teach-by-demonstration approach. With TwinTrack, users can manually teach a robot the desired path by performing the manufacturing operation themselves. The robot then replicates these movements with high precision. This method is applicable to a wide range of manufacturing applications such as painting, polishing, deburring, dispensing, or welding.

Teach-by-Demonstration

The teach-by-demonstration method employed by TwinTrack offers several advantages:

1. Ease of Use: Unlike traditional robot programming, which often requires complex 3D models and computer interfaces, TwinTrack allows operators to program robots by simply mimicking the desired operation with their hands. This user-friendly approach makes it accessible to those without extensive technical expertise.

2. Time Efficiency: By eliminating the need for 3D modeling and extensive computer programming, TwinTrack enables faster robot programming. This leads to quicker implementation of automation solutions and reduces downtime in manufacturing processes.

3. Versatility: TwinTrack is compatible with over six hundred robots from fifty different manufacturers supported by RoboDK. This flexibility ensures that businesses can integrate TwinTrack into their existing operations regardless of the robot brands they use.

Precision and Calibration

Accuracy is a critical factor in manufacturing, and RoboDK TwinTrack does not disappoint. The technology requires a 6D measurement system and a handheld probe or manufacturing tool to replicate the human operation. With a high-quality measurement system, TwinTrack can achieve position accuracy up to 0.150 mm, depending on the robot’s quality and size. Additionally, RoboDK’s calibration tools further enhance the precision of the robot programs, ensuring that the digital twin accurately mirrors the physical operation.

RoboDK TwinTrack offers a transformative approach to robot programming, making automation more accessible, efficient, and precise. By allowing operators to teach robots through demonstration, TwinTrack eliminates the need for complex programming and 3D models, accelerating the automation process and enhancing manufacturing productivity.

For more information and a visual introduction to RoboDK TwinTrack, check out the following video:

What questions do you have about manual teaching robots? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.