Manual finishing operations can be inconsistent and difficult to scale. When faced with a labor-intensive finishing process, Automax Robotics Pvt. Ltd solved this common problem by creating a robotic system with the help of RoboDK.

If you have ever tackled grinding or polishing tasks on the shop floor, you’ll know how quickly minor inconsistencies can build up. Finishing operations are physically strenuous for human workers, leading to variable surface qualities over the course of a long day.

Automax Robotics and India International House Ltd. (IIHL) knew this pain all too well. When manual finishing introduced increasing bottlenecks in their workflow, they looked for an automated solution…

Introducing… Automax Robotics Pvt. Ltd.

Automax Robotics Pvt. Ltd. is an innovative provider of advanced robotic automation solutions based in India.

Specializing in industrial and educational robotic solutions, the company is dedicated to redefining what is possible with robotic technology. As well as industrial solutions, they provide advanced robotics labs, training, and skill development programs, preparing teams and students to use robotic systems effectively.

CEO Sagar Mângulkar says:

“At Automax Robotics, we don’t just automate — we innovate with purpose. By combining robotic precision with adaptive intelligence, we’re not just solving today’s challenges — we’re building the foundation for the smart factories of tomorrow.”

For this project, the team turned their attention to a problem faced in their collaboration with IIHL.

The Client: Hardware Manufacturer India International House Ltd. (IIHL)

Based in Delhi, India International House Ltd. (IIHL) is India’s largest manufacturer and exporter of antique restored hardware, with over 40 years of experience supplying high-quality finished metal products to international markets.

With a global presence, the company’s strategic objective is to become the best and largest global supplier of finished metal products through continuous investment in modern machinery, product development, and sourcing capabilities.

One of IIHL’s products is polished door handles. For this, the team was using a manual finishing process that involved 4 separate finishing tasks, from grinding to polishing. This was becoming labor intensive and leading to inconsistent surface finishing.

Why Manual Finishing Wasn’t Enough

The team at IIHL were facing a common problem. Manual finishing was producing uneven results, introducing bottlenecks, and making it hard to meet their production targets.

This is a familiar issue with manual finishing. No matter how skilled the workers, manual surface finishing almost always leads to some consistency issues, which are exacerbated by labor shortages. Surface finishing is just one of several robotic applications that are becoming increasingly common in the furniture industry.

With a desire to scale production even further, IIHL called in Automax Robotics Pvt. Ltd. to reinvent the finishing process. Together, they saw an opportunity for optimization with robotics that could improve product quality and pave the way for efficient scaling of production.

The Solution: A Smart, Multi-Station Robotic Workflow

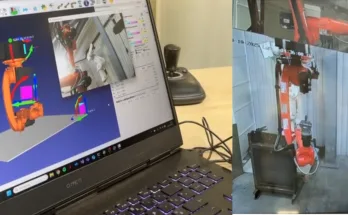

The team at Automax Robotics opted to design an entire robotic workflow based around a FANUC industrial robot. Using a custom end effector, the solution operates across four Lancer grinding machines, handling each part sequentially.

The aim of the system was to ensure high-quality, repeatable results with reduced manual involvement.

The Hardware

The hardware components were:

- Robot – A FANUC M-10iD/12 industrial manipulator

- End Effector – A custom-built pneumatic gripper

- Finishing Machines – 4 Lancer belt grinders

The Software and Control System

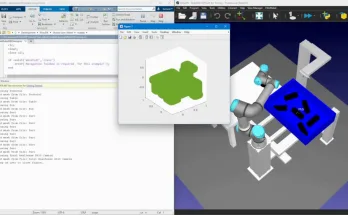

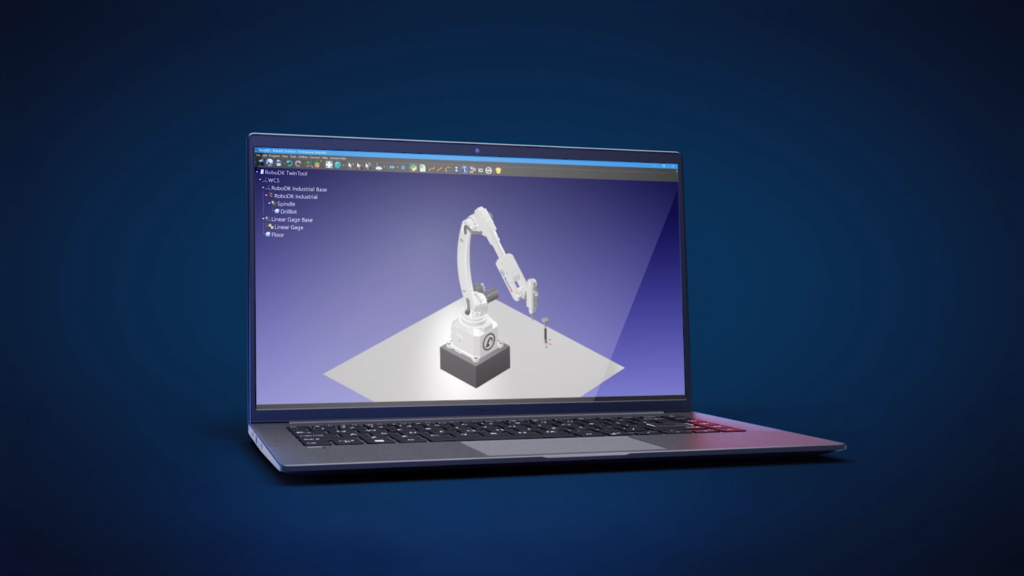

Based around RoboDK, the software solution allows for both offline and online programming.

The control components were:

- Robot Programming and Simulation Software – RoboDK

- On Robot Programming— FANUC Teach Pendant

- Control System – A Programmable Logic Controller (PLC) with pneumatic interfacing and safety systems

How the Door Handle Finishing Application Works

The resulting solution enables completely automated finishing of door handles. Each door handle goes through all 4 of the finishing stages, held by the custom pneumatic end effector developed by Automax Robotics.

Each machine performs a different finishing operation. The robot picks up a door handle and processes it through four grinding stations in sequence. All paths and programming logic steps were pre-programmed and simulated in RoboDK. The robot program was then uploaded directly to the robot for precise execution on the shop floor.

Ideal users of the solution include manufacturers and integrators handling multi-step robotic operations, especially where accuracy, consistency, and adaptability are critical.

The team said:

“RoboDK’s simulation-driven workflow is especially helpful for teams that want to iterate quickly and avoid trial-and-error programming on live systems.”

What’s Next? Adaptive, Data-Driven Automation

The current solution is only the beginning. The team at Automax Robotics has more plans to grow this development for other clients and use cases.

One of the first additions they plan is to integrate a 4-axis force-torque sensor onto the FANUC robot to capture real-time polishing pressure. Using RoboDK, this will allow the robot to adapt dynamically to changing forces in the polishing tool. This will allow the solution to handle part variations intelligently while maintaining a consistent surface finish.

The team is also looking to move beyond finishing tasks by adapting the same approach for other robotic applications. They plan to scale the approach across future projects involving welding, gluing, and smart inspection. To facilitate this connection, the team will use its in-house Smart Connect software platform.

Offline Programming Allows Real-World Consistency

Automax Robotics and its partnership with IIHL demonstrate the great power of robotic automation for solving common manufacturing challenges.

By integrating a FANUC robot and RoboDK software, they created a multi-station workflow that delivers consistent, high-quality door handle finishing while removing bottlenecks in production. This innovative solution addresses production challenges and paves the way for scalable, adaptive automation powered by RoboDK.

If you have ever faced challenges with manual finishing, download a trial copy of RoboDK to see if it works for you.

What aspect of this success story is most familiar to your situation? Join the discussion on LinkedIn, X, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel