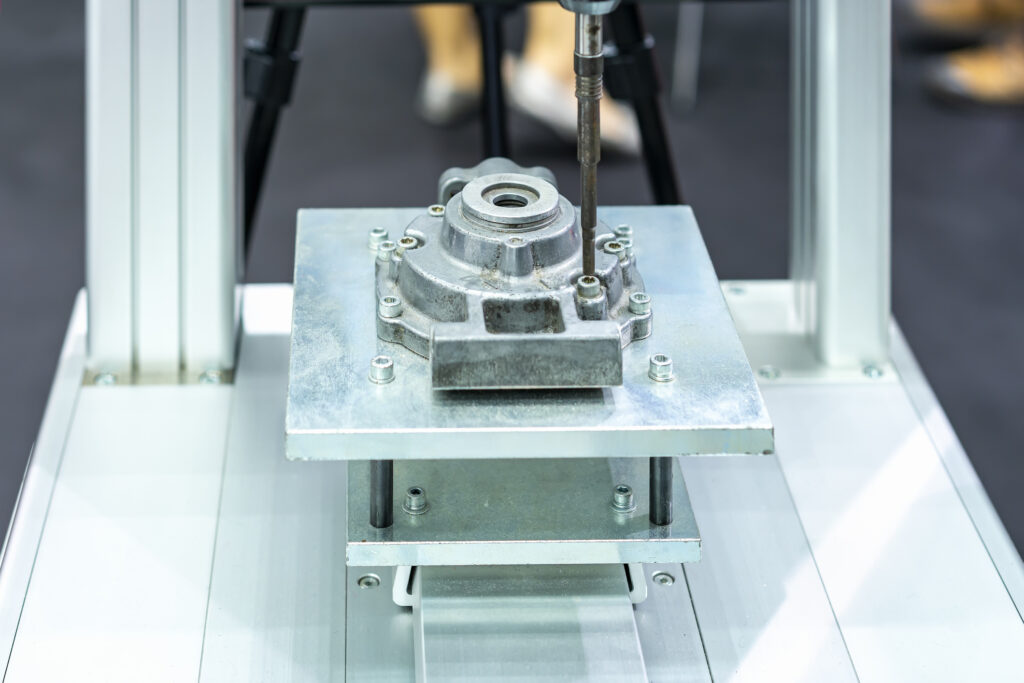

Screwdriving is the most common way to assemble parts in manufacturing. Automated screwdriving can help you to improve the consistency, productivity, and profitability of this fundamental task.

According to Assembly Magazine’s annual survey, 58% of all assembly plants in the USA have screwdriving tasks. This makes it more popular than welding, pressing, adhesive bonding, and riveting.

Automated screwdriving can be a great way to improve your assembly process. But, not all solutions are equal in their effectiveness. If a solution isn’t flexible, you will struggle to adapt it to keep up with changes in your process.

What’s the most flexible approach to automated screwdriving?

Among the various automated solutions you could choose, one comes out on top if you’re looking for flexible screwdriving automation…

What to Look for in an Automated Screwdriving System

When you are looking to automate a screwdriving task, there are a few properties that you should look out for. This will help you to make easier, better decisions about which system will best suit your needs.

In fact, properties that are important in an automated solution include:

- Speed — How fast do you need the system to be able to work? What’s your desired throughput?

- Flexibility — Will the system be used for only one screwdriving task forever? Or do you want to use it for different screwdriving tasks?

- Compatibility — Is the solution compatible with your desired screwdriving bits?

- Cost and return — How much does the system cost and, most importantly, what is the payback time for the investment?

- Ease of programming — How easy is the system to program? How much robotics experience does it require from users?

With these properties in mind, you can assess the various automated screwdriving solutions on the market.

3 Types of Automated Screwdriving Solution

You can arrange most of the different automated screwdriving solutions into the following 3 types. Each will be suited to slightly different situations.

Semi-automated screwdriving

The simplest form of automated screwdriving, semi-automated systems still require human intervention.

The most basic systems are just handheld power tools fed with an automatic screw feeder machine. More complex systems can involve robots or other forms of automation with the human worker loading and unloading each workpiece into the machine individually.

Conventional automated screwdriving systems

There is an ever-growing range of automated screwdriving systems. Most of these conventional-style systems tend to be best for “all or nothing automation” where you automate the majority of your production.

Conventional automated screwdriving systems can handle very high throughputs. As many are custom designed, they aren’t very flexible to changes in your products.

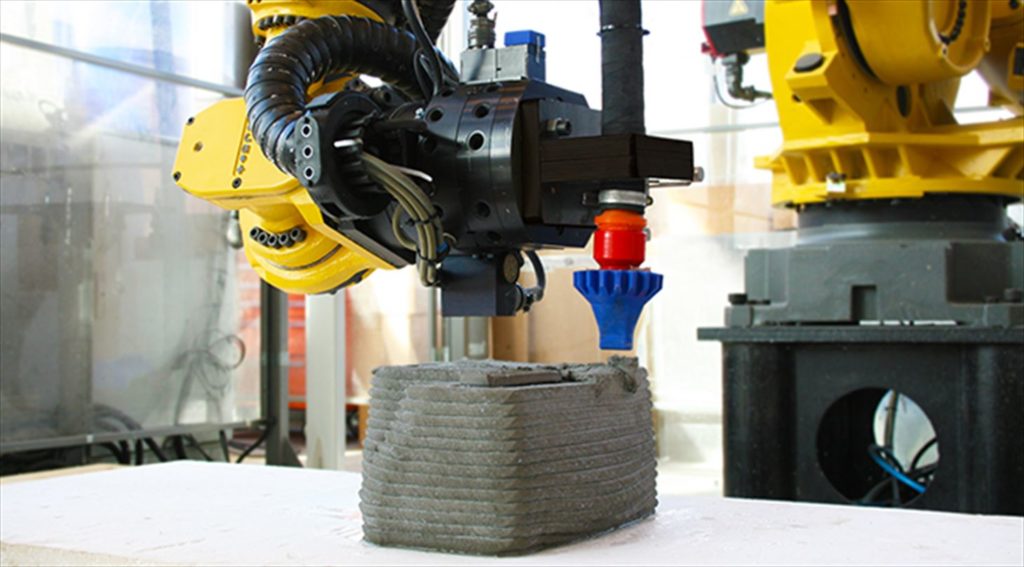

Industrial robot screwdriving

Robotic screwdriving has been growing in popularity recently.

It offers a more flexible approach to screwdriving automation than the conventional solutions. With the right system, you can quickly reprogram the robot to respond to changes in your workflow.

Why Robotics is the Most Flexible Automated Screwdriver

What makes robotic screwdriving more flexible than the alternatives?

Let’s look at the process of deploying a conventional automated screwdriving to a facility compared to a robotic system.

With a Conventional Automated Screwdriving System

With a conventional system, the steps would be:

- The automation supplier would come into your facility and assess your screwdriving task.

- They would go away and design a completely customized solution to fit your facility.

- The system would usually be big. The more complex your assembly process, the more parts your system would need.

- “Programming” is done by designing the flow of each part through the automated machine and adding a new automated component for each step.

- If you ever need to change your assembly process, you need to redesign and rebuild part of the machine. This can take months.

With a Robotic Screwdriving System

With a robotic system, the process is much simpler:

- The design process is usually quicker and easier as the complexity is handled by the robot’s programming.

- The system tends to take up less space in your facility as there is only the robot and any necessary extras. The size of the system doesn’t grow with the number of screwdriving steps.

- Programming is done with a dedicated robot programming tool.

- If you ever need to change your assembly process, you can tweak and redeploy the robot program in a matter of minutes or hours (depending on the extent of the changes).

This ability to reprogram the robot quickly and easily is what makes robotic systems so flexible. This makes robotic screwdriving more suited to many more companies as it allows automated screwdriving even in highly changeable production environments.

Thus, with robots, automated screwdriving is no longer only for companies producing high-volume and highly consistent products.

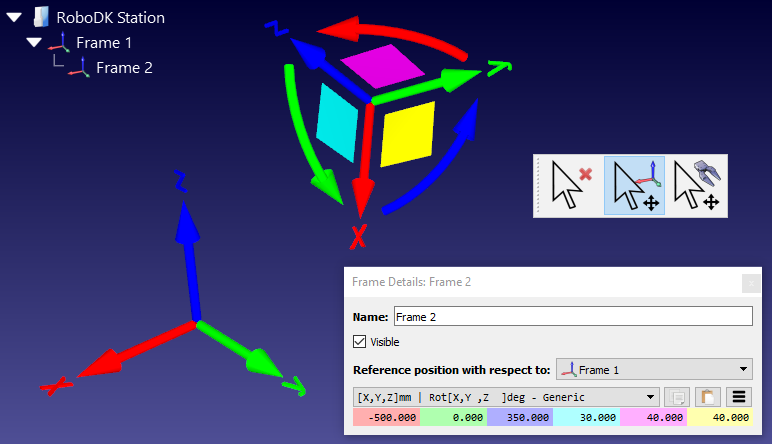

How to Program a Robot Screwdriving Solution Quickly and Easily

Your programming tool is fundamental to creating an effective robot screwdriving task. Indeed, with the wrong programming approach, a robotic system can be as inflexible as conventional screwdriving automation.

What is the easiest, most flexible way to program a robot for a screwdriving task?

An offline programming tool, like RoboDK can help you to program your screwdriving task very quickly.

The programming process for robotic screwdriving is very similar to a drilling task. The robot moves to various points on the surface of the workpiece where the screws are located.

With RoboDK, this means you can program a screwdriving task with our Points Follow Wizard. Also, you can load the screwdriving points directly from your favorite CAD/CAM package.

Finally, learn how to create a Point Follow Program in RoboDK on our documentation page.

What screwdriving tasks would you like to automate in your facility? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel