You might see the benefits of robot machining… but does your boss? Here’s how to convince management to approve your robot machining project.

Have you ever had great ideas you wanted to share with your boss on how you can improve your business?

We can see the benefits that a new technology or approach will bring to our workshop. But, management might say that there’s “not enough budget” or “not enough time.”

Robot machining can be a game-changer for your business. A machining robot can simplify your life and even outperform traditional CNC machines.

You are probably aware of the benefits that robot machining can bring to your workshop or production line. Still, management might not be so convinced… or at least, not yet!

Here’s how you can convince management to get your robot machining project approved.

Why Management Might Not Agree to Robotic Machining

Imagine you go to your boss with a proposal to start using robotic machining… and they say no.

What reasons do you think they might have for this rejection?

In these situations, we are often quick to blame the management. We might say that they are “blind to new technologies” or they are “too focused on cutting costs.”

While these may have an element of truth in some rare cases, they are quite unlikely. In most cases, people who are in management are very committed to making the business successful. It is in their interest to make the business run as effectively as possible.

Although you can probably see the benefits of robotic machining, they might be more likely to look at the risks.

5 Common Concerns About New Robotic Technology

In the first place, your boss probably doesn’t hear the benefits of robotics. Instead, they hear “new robotic process” and think of any one of many problems, including:

- “It costs too much”. — Probably the most common concern. For many, automation equates with high cost.

- “The ROI is long and uncertain”. — Managers might think about Return on Investment instead of the up-front cost. They’ll be put off if they can’t see a clear payback time or they think it will be too long.

- “We’re too busy with other operations”. — Instead of the potential time-saving benefits that robot machining could bring, your boss is thinking of all staff hours that it will take.

- “Automation will be unpopular”. — The media is filled with stories about “robots taking jobs”. Management might think that the workforce will resist.

- “We don’t need robot machining.” — You are probably proposing robot machining as an alternative to existing manual or CNC processes. However, management might not see why a robot is any better than what you have already.

It’s important to address these concerns directly rather than ignoring them. Management is much more likely to accept your proposal when you demonstrate that you have understood their concerns. Even better, you have come up with a strategy to overcome them.

6 Steps to Ensure a Successful Proposal

Creating a successful proposal for robotic machining requires several preparation steps.

That means that you need to do a bit of “homework” if you want your proposal to be accepted.

Here are 6 steps to build a watertight proposal that will convince management that robotic machining is a good solution:

- Assess the suitability of robotic machining. — Before presenting your solution to management, you first need to be sure yourself. Take some time to clarify the specific problems that robotic machining will solve.

- List the benefits and tangible improvements. — If you’ve been looking into robotic automation for a while, you probably have an intuitive feeling. List the potential benefits to your manufacturing process and, where possible, add specific numbers to them.

- Find out what is important for your boss. — You will have a much better chance of having your proposal accepted if you present the benefits in a way that directly speaks to your boss’s main concerns. For example, if they’re always talking about cutting costs or increasing production it’s likely that these are important to them.

- Convert the benefits into language they will understand. — This is where the “Jedi Mind Trickery” of the process comes in… well, okay maybe not quite mind trickery. However, you will skyrocket your chances of success if you “translate” the benefits in a way that directly speaks to your boss’s top concerns. For example, if your boss is most concerned about growing the business, instead of saying that robotic machining will “make machining more flexible” you could say “allow us to produce bigger workpieces which would allow us to serve new markets.”

- Build and rehearse your proposal. — Every proposal, no matter how small, can benefit from some good rehearsal. For instance, you can write down the proposal but also make sure that you can present it out loud with confidence.

- Present your proposal and follow-up. — Having done the “homework” you can now present your case for robotic machining to the management. Make sure to answer any questions and follow up by sending details of the proposal in writing.

Improve Your Chances of Success With a Simulation

A picture is worth a thousand words, they say.

How many words do you think a functional simulation of the robot is worth? Probably millions!

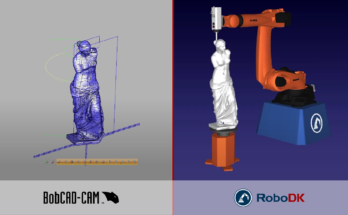

Finally, you can improve your chances to convince management to robot machining even further: Create a simulation of your application in RoboDK. Check out how to create a robot machining simulation and robot program in just a few steps.

You can also learn more by trying our plugins for Autodesk Fusion 360, Mastercam, Autodesk Inventor or MecSoft/RhinoCAM.

Have you ever had a proposal knocked back by management? Why did it happen? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram or in the RoboDK Forum.