Precision cutting and drilling can present significant challenges, especially in the face of labor shortages and lack of skilled machinists. Robotecki, a Brazil-based leader in robotic innovation, recently mounted a project to tackle this problem with an innovative robotic solution powered by RoboDK.

With their application, the team at Robotecki not only reduced labor-dependency for these key tasks, they improved the quality of production and throughput.

Here’s how the team achieved all this with RoboDK…

Introducing… Robotecki

Since its inception in 2013, Robotecki has become known for its innovative solutions for high-performance machining. Based in Rio Grande do Sul, Brazil, the company has built a strong reputation for creating custom robotic solutions across various industries.

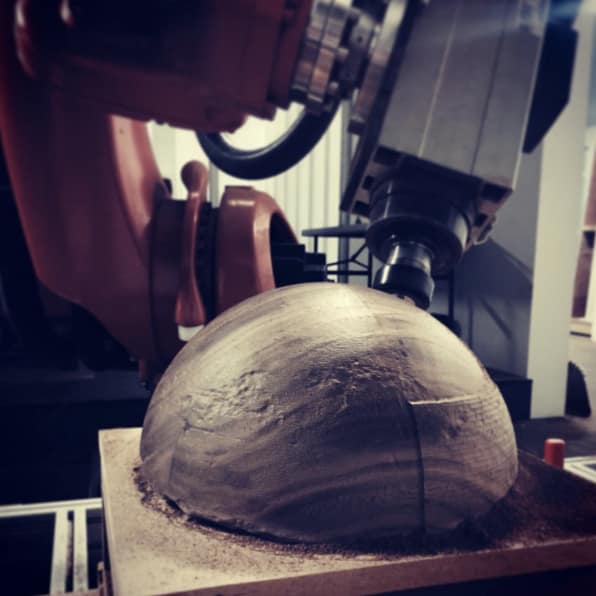

Robotecki’s projects are as wide-ranging as they are impressive. Highlights of their expertise include everything from fiber and wood machining to artistic fabrication of large statue projects.

The company’s philosophy is simple yet powerful:

“At Robotecki, innovation is in our DNA! Our commitment is to offer excellent products and responsive support, making our customers the greatest advocates for our brand.”

With expertise tackling projects for large companies in challenging sectors — such as part production for aerospace — they develop robotic cells using cutting-edge technology.

With this latest success story, the team at Robotecki showcases the immense potential of robotic automation for tackling the most complex industry challenges.

Labor Shortages, Part Variability, and Quality Concerns

Labor scarcity is one of the most pressing issues facing many manufacturing industries these days. Traditional time-intensive manual processes are increasingly becoming a bottleneck to production. Such processes increase costs and often lead to inconsistent product quality.

For this project, Robotecki’s team were also faced with a unique problem: high part variability. There was no standard for parts to maintain consistency. This exacerbated the situation, making it increasingly difficult to ensure consistent high-quality cutting and drilling.

But challenges also lead to valuable opportunities.

The team recognized they were dealing with a trifecta of challenges that are common in modern manufacturing:

- Labor Shortages — Many of the time-intensive processes in manufacturing can be fully or partially addressed with robotic automation. This helps optimize the use of human workers.

- Part Variability — Variability Reduction is essential in modern manufacturing, where sustainability, cost efficiency, and waste reduction are at the forefront of everyone’s minds. Robots can optimize processes, making them more efficient over time.

- Quality Concerns — Manufacturing high-quality products quickly and efficiently involves a continuous balancing act for manufacturers looking to scale. Robots can provide a key technology in this task, as they provide high consistency.

Robotecki realized they could address these challenges with a single robotic application. By devising a project using RoboDK at its core, they combined various technologies into a single solution.

The Solution: High-Precision Cutting and Drilling with RoboDK

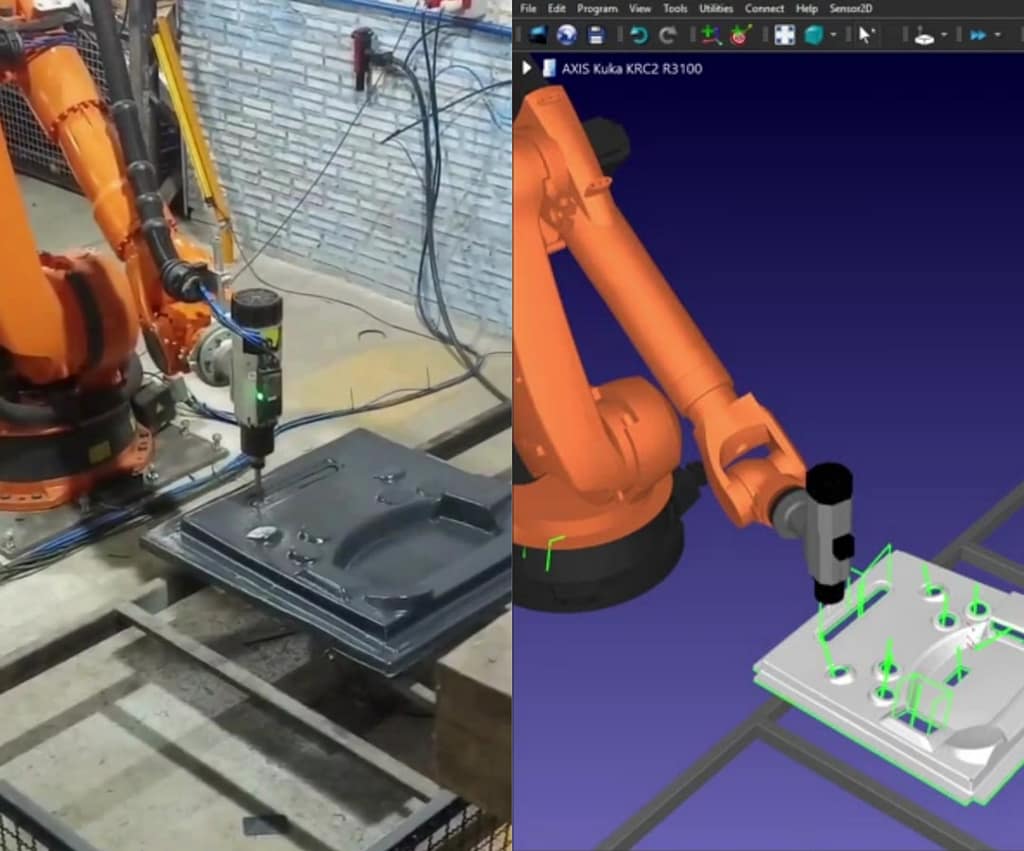

To overcome these challenges, Robotecki designed an automated robotic cell for precision cutting and drilling applications.

By integrating various advanced technologies, this system provides a combined solution for manufacturers looking to meet the stringent quality requirements while adapting dynamically to part variability.

Here is how Robotecki designed their solution:

The Hardware and Software

The solution is based on several key hardware and software components, with RoboDK at the center of the software stack.

First, the hardware components that the team chose are:

- Customized End Effectors for Drilling and Cutting — These specialized tools were designed to handle the specific requirements of precision cutting and drilling.

- Automated Tool Changing — The system includes a tool-changing mechanism that allows the robot to switch between different tools on-the-fly to eliminate the need for manual tool changing.

- 3D Scanning Hardware for Part Analysis — Through 3D scanning, the system captures the exact geometry of each part, helping to manage the part variability.

The software components are:

- RoboDK for Simulation and Offline Programming — RoboDK’s powerful simulator serves as the software backbone of the system, enabling the team to optimize the robot’s movements in a simulated environment before deploying to the physical robot.

- Fusion 360 for Machining Path Creation — The leading CAD/CAM program Fusion 360 was chosen for creating detailed machining paths. With RoboDK’s dedicated plugin for Fusion 360, this process is simple and streamlined.

By combining these components, Robotecki created a solution that not only meets the demands of modern manufacturing, but also sets a new standard for precision and efficiency in robotic cutting and drilling.

The Role of RoboDK in Streamlined Development

RoboDK proved instrumental in the success of this project.

From refining the cutting process to mitigating hardware limitations, the software’s capabilities empowered Robotecki to:

- Optimize accuracy in simulation to eliminate unnecessary iterations on the shop floor.

- Simplify robot adjustments and calibration steps to ensure consistent machining.

- Accelerate deployment to bring the system online faster than with traditional methods.

The team explained:

“RoboDK helped in the development of the cutting process, facilitating adjustments, movements, and limitations of the robot’s axes. Each part was also scanned to obtain the 3D image and program it in Fusion. It was then implemented in RoboDK! “

This created a system that is an excellent fit for manufacturers working with challenging materials like thermoformed parts and fiberglass. The system’s adaptability, coupled with easy programming workflow, makes it especially valuable for businesses prioritizing precision, scalability, and process simplification.

The Next Steps for Robotecki

What’s next for the Robotecki? The team views this success as a stepping stone toward broader innovation through robotics in the future.

They aim to expand their applications, focusing first on confronting similar challenges to the ones addressed in these projects. From there, they aim to continue to develop applications that facilitate programmers to have a more streamlined and accurate process.

If you would like to use RoboDK as the basis for your project, check out our simulation page to see what it can do.

Which of the three challenges do you most often face? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel