If you’re like us, you love new features that make your life easier when programming your robot. That’s why we’re excited to share with you the new RoboDK updates that we’ve made as of May 2022.

We’ve designed these updates to make robot machining, fabricating and all other robot programming tasks faster, easier, and more intuitive.

Since our last product update in March, we’ve added a huge 25 updates to the software to make RoboDK even better. That includes 7 bigger changes and a bunch of smaller ones.

Keep reading to see what’s new…

1. Improved Support for SCARA Robots

SCARA robots are a mainstay of many manufacturing businesses. They are often used in assembly and pick and place applications because of their high speed and precision.

At the time of writing, we support 70 SCARA robots from 19 manufacturers. In the past few years, we have doubled our support for SCARA robots.

Recently, we have improved our support for SCARA robots. A few of the changes we have made include:

- Improved program generation for FANUC SCARA robots.

- Changing the name of the official FANUC post processor to Fanuc_R30i.

- Improved support for SCARA robots all round.

2. Improved KUKA Drivers

We are always looking for ways to improve our software and make your life easier. When a robot manufacturer updates their products or makes unexpected changes, we take those into account.

We do this by making updates to RoboDK so it will elegantly handle any situation thrown at it!

We’ve made some slight changes to our KUKA drivers. These will make it easier for you to program KUKA robots if you are using these features:

The recent changes include:

- Improved KUKA driver to get/set variables without disconnecting from the robot controller.

- General improvements to all our KUKA drivers.

- Improved KUKA SRC import script to support external axes.

3. Added Support for Comau Nodal Language

We have just included an exciting new update if you are using Comau robots.

Comau is a popular robot manufacturer based in Italy. Their robots are programmed with the PDL2 programming language, which is a Pascal-like language specific to their robots. Comau offers several teach pendants and some different programming approaches. Until now, RoboDK’s support has centered on their C5G teach pendant with the normal PDL2 programming approach.

One feature of PDL2 is an alternative node-based programming approach. We have now added support for this approach. You can find it in RoboDK as a new post-processor for Comau. This provides more configuration options than our existing post processor.

4. Improved Mechanism Creation

At RoboDK, we always prioritize flexibility and wide support for different robots. Our software already natively supports hundreds of robot models from dozens of robot brands, which you can find in our Robot Library.

But you don’t need to use one of the already-supported robots. You can use absolutely any robot mechanism with RoboDK.

It’s easy to create your own robot mechanism in the software using our Mechanism Wizard.

We have recently made a few changes to the mechanism creation. These changes include:

- Improvements to the generic 6 DOF mechanism kinematics.

- Setting the default new mechanism to be a 1-axis turntable. This makes sense because one of the most common type of mechanism people want to add is a simple external axis.

5. Improved tools for Robot Machining

Robot machining is an application that’s rising in popularity right now, and for good reasons. It is a great way to expand your machining capabilities, increasing the size and complexity of your machining tasks in a very cost effective way.

We have included several extra tools in the latest version of RoboDK to make it even easier than it already was to create machining paths.

Updates that we have made to our robot machining tools include:

- Improvements to RoboDK’s automatic curve extraction and modification tools.

- The option to set current joints is now always visible in the robot machining menu.

- Improved NC code import to allow custom program calls.

- An added option to have more decimal places to create robots, allowing for more precision in robot machining.

6. Some More Small Changes for Easier Robot Programming

We have also added a bunch of other small changes to make your life easier as you program with RoboDK.

These changes include:

- Adding the option to align a reference frame using a right click, making this step even faster.

- Improved options to run programs on the robot vs. the station. This can be useful for more complex robot programs with various moving parts.

- Added the option to align targets, making it easy to quickly align parts of your robot program.

- Added the option to change the support of multiple references at once.

- Improvements to the post processor selection menu.

- Added the option to import Mecademic scripts, a specific type of program for this robot brand.

- Improvements bulk editing program call instructions.

- Improved icons, making everything look a little neater.

- Officially added the plugin to attach a part to a robot link (PluginAttachObject)

7. Improved the Matlab API (and further improved Python)

Earlier this year, we completely refactored our Python API. These changes set up the programming interface for future updates of the software and make it even more intuitive to program your robot with Python.

Now, we’ve also improved the Matlab API!

Matlab is an extremely popular software tool in data science and robot research applications. It includes powerful features to analyze and optimize your robot designs. With the API, you can control your robot directly within your Matlab programs, extract joint positions, and use the extensive range of Matlab libraries to improve your robot programs.

And a Big Announcement: Introducing TwinTool

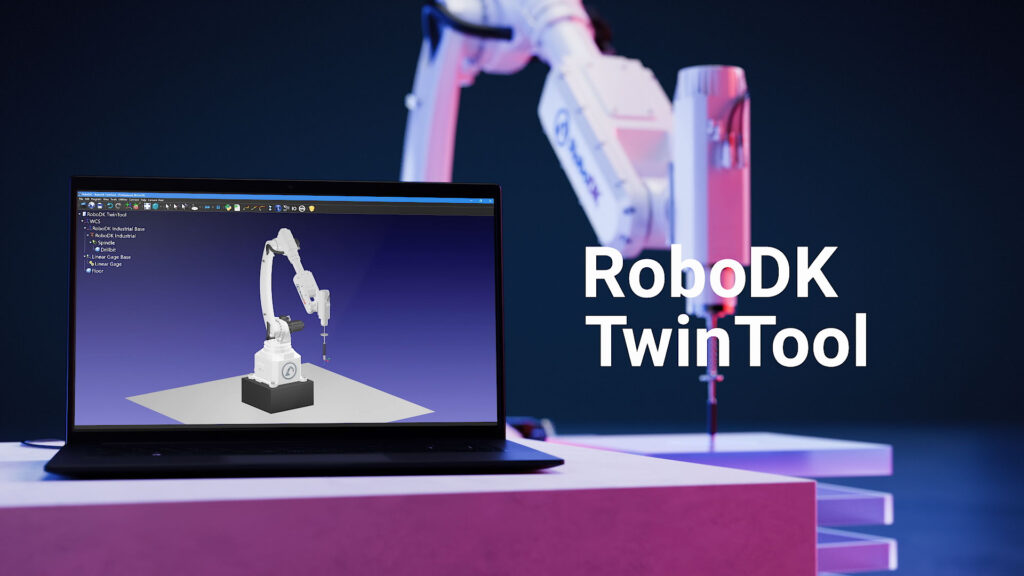

We also have a brand new product that we have just launched: RoboDK TwinTool.

TwinTool provides an easy and cost-effective way to improve the accuracy of your robot tool. It uses an off-the-shelf linear gauge to calibrate the robot’s tool center point (TCP). Users often overlook this valuable step, but properly calibrating the tool center point can make all the difference when trying to achieve an accurate robot program.

Learn more about TwinTool in our product page.

Do You Have a Feature Request You’d Like Us to Consider?

That’s all for this month!

We hope you find these updates helpful. Our team of experts is always working hard to improve our software and make robot programming more accessible to everyone.

As always, if there’s a feature you’d like us to add, submit a request in our forum.

In the meantime, happy robot programming!

Do you have any feature requests? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel.