Abstract shapes are one of the big challenges for fabrication. But, they are becoming more and more common in architecture.

How can architects untie themselves from the restrictions of traditional construction methods?

One research team has found an ingenious way using RoboDK and Grasshopper.

In a world of architecture, easy-to-manufacture shapes have traditionally been made up of regular, straight lines. This is why buildings tend to feature smooth, vertical facades with very little variation from one building to the next.

But, times are changing.

Recently, architects have found ever more ingenious ways to break free from the restrictions of traditional building methods. We are now becoming more familiar with the sight of strangely shaped buildings with interesting, varied appearances.

The facade of the building (its front-facing appearance) is key to creating these interesting shapes. But, it can be difficult to fabricate complex facades in a way that is quick and cost-effective.

This is exactly the problem that one research team has tackled with RoboDK.

Introducing… the Building Envelope Research Group

The Building Envelope Research Group (BERG) is based in the Anhalt University of Applied Sciences in Köthen, Germany.

BERG’s primary focus is to expand the “scope of the building envelope” with new and innovative fabrication methods, looking at materials, construction techniques, technology, and energy. Their current research projects range from methods to create self-sufficient ventilation systems through to the development of bendable acoustic panels.

The group got in touch with us because they were using RoboDK for one of their research projects.

This project used an interesting approach to robot manufacturing to create forms for abstract concrete facades.

Why Abstract Facades Are Tricky to Fabricate

Many different materials can be used to create a building facade. Common options include wood, metal, stone, and masonry. However, one of the most versatile options is concrete.

Concrete has an advantage over other materials because it is cheap, hard-wearing, and extremely adaptable. As it begins in liquid form, you can create almost any shape that you can imagine… as long as you have a method to hold the shape of the wet concrete as it sets.

The challenge, therefore, comes in the creation of forms to hold the shape of the concrete facade panels. If you want to create interesting abstract shapes out of concrete, you need to create equally interesting abstract forms that are capable of supporting the wet concrete.

Common options for creating such forms include

- Creating a mold out of wood, rubber, or metal.

- Using a flexible table with actuators and membranes to alter its shape.

- Using a CNC machine to mill a form out of foam or plastic.

These are all good options but they can be expensive and take a long time to create. For example, flexible tables are quick to reconfigure into a new shape, but the upfront machine cost is very high. CNC milled foam takes 5-10 hours to create and can only be reused 5-10 times before they need to be remade.

Why Use Abstract Facades At All?

You might wonder why we want to create abstract facades for buildings at all.

Of course, the main reason is aesthetics — they look good. However, modern facades are not all about aesthetics. The design of the facade can also enhance the sustainability of the building.

Facades are also a great place to test out new fabrication techniques, as the team at BERG demonstrated in their project.

The Project: Creating Abstract Forms for Fiber-Reinforced Concrete

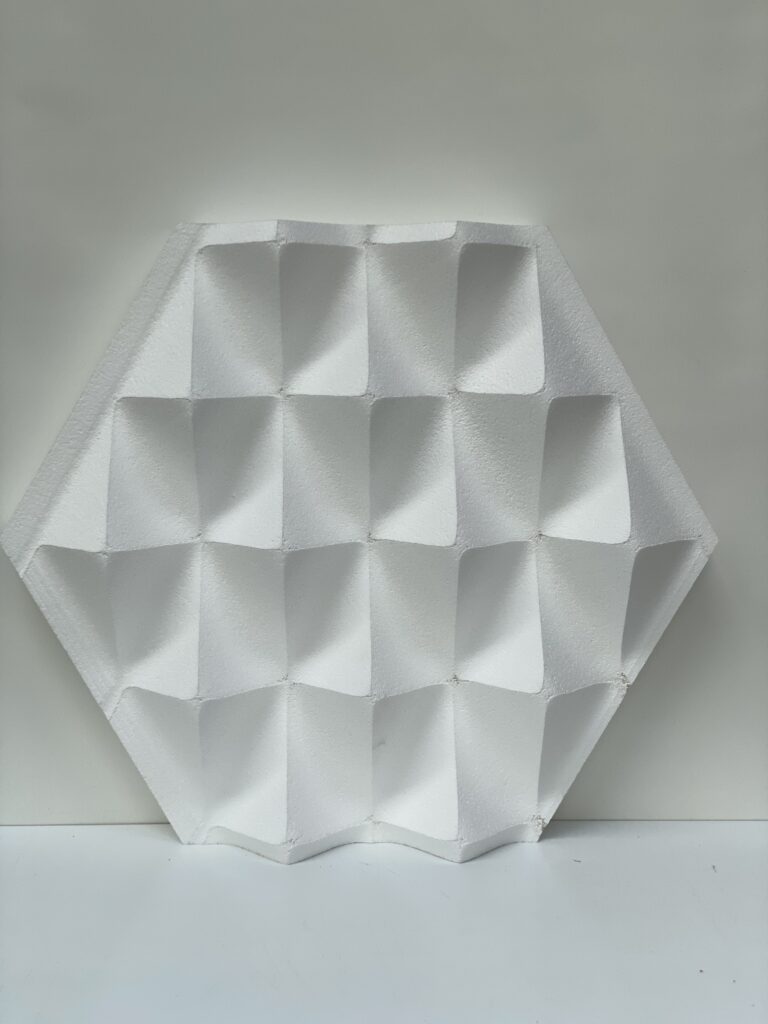

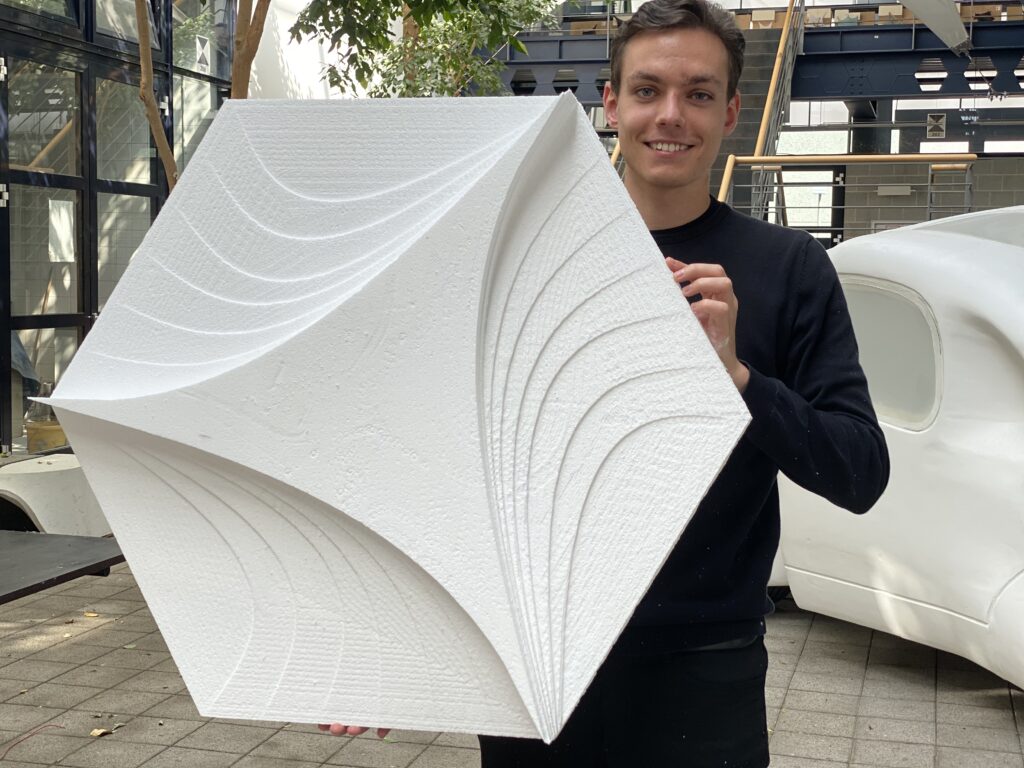

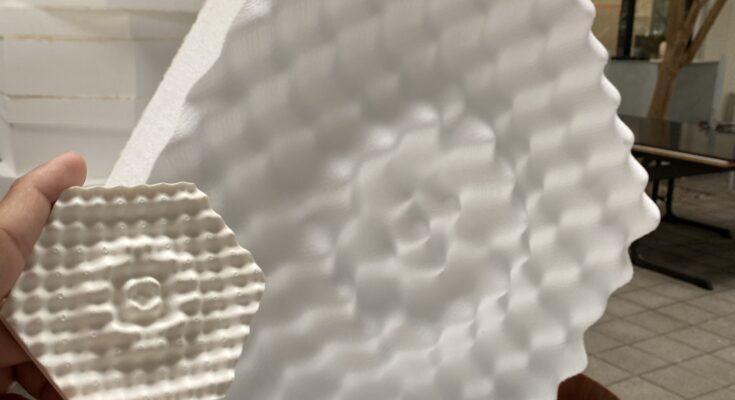

The team decided to use robot fabrication to create styrofoam molds for the concrete, which was reinforced with glass fibers.

The robot used a hot wire to cut the styrofoam blocks and was programmed via RoboDK.

To handle the abstract shapes, they chose the CAD package Rhino due to its parametric modeling capabilities. Parametric modeling allows designers to create previously unimaginable structures easily and it is often used by architects for this reason. We previously discussed the benefits of using Rhino with RoboDK in our article 6 Amazing Things You Can Do With Rhino and RoboDK.

They first designed their CAD model within Rhino (and its algorithmic modeler Grasshopper) and then used the RoboDK Rhino plugin to send these designs directly to their robot.

As the team at BERG is largely focused on material properties, a major part of this research project involved testing the structural properties of the concrete after it was formed in this way.

One important property was the surface finish. They found that they could vary the detail of the surface finish by changing how quickly they moved the robot. Slower speeds led to a smoother surface finish.

The Robotic Setup

The robotic hardware that the team used was as follows:

- Robot: A KUKA KR 16-2 6-axis industrial robot.

- End effector: A metal rig on which was mounted a hot wire to cut the styrofoam.

- Table: The styrofoam block was fixed to a table, ensuring that it didn’t move during the cutting operation.

- Programming setup: Rhino and Grasshopper for CAD design and structural (FEA) analysis, attached to RoboDK via the plugin.

Benefits of Using Robot-Fabricated Styrofoam for Facades

There were several benefits that the team found with their method compared to the more standard approaches to concrete facade fabrication.

These included:

- It was cheaper — The up-front costs for this method were less than those with other methods of form production. For example, CNC milled forms cost up to €400 per square meter. With this method, the cost was only €30 per square meter.

- It was quicker — The time to create the form was only 1 hour. With every other type of manufactured form, it would take between 2-10 hours to create. The only faster option would be to use the costly flexible tables.

- It was flexible — Unlike other options, the only limit to this method was the reachability of the robot and the dimensions of the cutting wire. This increases the flexibility of this method.

For more information about this project, check out their research paper.

What architectural projects can you think of for robotic fabrication? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.

Interesting article.

I would argue, however, that your description of the third benefit of their aproach – “Unlike other options, the only limit to this method was the reachability of the robot and the dimensions of the cutting wire.” – is a bit too generous.

Not only do the robot’s reach and the dimensions of the wirecutting tool limit the design possibilities, but in fact the hot wirecutting technique in itself is limited to creating a particular class of surfaces called ‘ruled surfaces’.

While there is still a lot of scope for design with rules surfaces, the technique nevertheless is limited to this type of surfaces and there are many surfaces that this technique cannot create but 5-axis milling of styrofoam can produce.

The technique is also limited to creating surfaces that reach the edges of the starting block of material – you cannot create holes in a block of material with this technique, even holes who’s surfaces are rules surfaces.