Which robot palletizing system will be best for you? There are many options from many different brands. How can you pick the right one for your needs?

You’ve got a palletizing operation and it needs to be automated.

Your packaging process is just too slow to keep up with the throughput that your production requires. You know that automating the palletizing step is the only way to achieve the throughput that you need.

Conventional automated palletizing solutions can take up a huge amount of space on the factory floor and you don’t think they are suitable. They just aren’t flexible enough for the varied palletizing tasks that you use in your business.

A robot seems like the best solution.

Palletizing may seem like quite a simple application — you are only arranging and stacking objects onto a pallet. You might assume that there are only one or two different solutions for automating a palletizing task in your business.

But, there are a surprising number of robot palletizing systems available.

Which one should you choose?

Should You Choose a Non-Robotic Palletizing Machine?

Of course, robotics is not the only option when you are considering palletizing automation.

Sometimes the more conventional type of palletizing automation will be better suited to your situation. For example, if you are palletizing thousands of identical products per minute in a fully-automated, high-volume production line, there is a distinct possibility that non-robotic palletizing solution might be a good option.

The main alternative to robotic palletizing is known as a layer palletizer.

Layer palletizers are huge, multi-level machines that sit towards the end of a production line.

Products are fed into the machine via conveyors. They are moved to the right position and orientation using actuators or fixtures along the conveyor. The layer palletizer then squashes the products together then pushes them onto a movable floor. The floor is then lowered onto the pallet. Finally, the floor is opened and the layer of products drops onto the pallet.

One of the major problems with layer palletizers is that they don’t accommodate mixed pallets or changeable product sizes and shapes. They also have strict restrictions as to the type of packaging material that can be handled in the machine, with light, delicate, and fragile objects being difficult or impossible to accommodate.

Robot palletizing systems, on the other hand, are highly adaptable.

Flexibility: The Major Benefit of Robot Palletizing Systems

Probably the greatest benefit of robots in any situation is the flexibility that they bring to your operations.

Unlike conventional layer palletizers, a palletizing robot can easily handle mixed pallets with products of various sizes and shapes. As long as the arrangement of products on the pallet will be secure during transit, you can almost certainly achieve your chosen palletizing task with a robot.

Many objects that are suitable for robotic palletizing are just not feasible with layer palletizers, including large sacks, heavy drums, and fragile parcels, to name just a few.

There is also a range of end effectors that you can use to adapt your robot palletizing system to different objects, including vacuum grippers, customized grippers, and even unique futuristic grippers for specific applications.

3 Types of Robot Palletizing System You Could Consider

Even when you have decided that you definitely want to use a robot for palletizing, there are still some decisions you have to make.

Several types of robot are suitable for palletizing tasks. Which you choose will depend on the needs of your task.

Here are the 3 most common types of robot used for palletizing, from least common to the most common:

3. 6-axis Industrial Robots

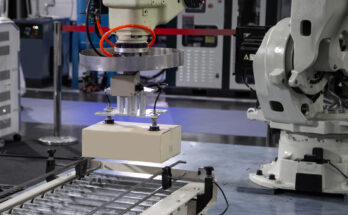

The high-performance, high-flexibility end of industrial robotics, 6-axis robots are suited to a whole range of tasks from welding to 3D printing. Using a 6-axis industrial robot for palletizing is certainly possible — with the right end effector — and can be a good option if you will want to use the same robot for tasks other than palletizing at some point.

2. Collaborative Robots

Rising in popularity, collaborative robots are generally smaller industrial robots that are safe to operate around humans. This increased safety can mean that their performance is lower than other types of robot, particularly in the speed that they can achieve and their payload. If you are looking to palletize a small number of products to move a worker away from a boring palletizing job, collaborative robots could be a good option.

1. Dedicated Palletizing Robots

Probably the best option for most palletizing tasks is to go for a dedicated palletizing robot. Unlike 6-axis industrial robots, these usually only have 5 axes as the end effector only ever needs to be pointing downwards. They also tend to use axis coupling, a feature that allows them to handle heavier payloads without reducing the speed.

Palletizing robots range in specifications from payload capacities from 8kg (e.g the GSK RMD08) to 800kg (e.g. the Motoman MPL800). You can find a wide selection of palletizing robots in our Robot Library.

Some Questions to Help You Choose the Right Robot Palletizing System

Here are a few questions you can ask yourself to determine which robot model, end effector, and other accessories you might need:

- What are the size, shape, and material properties of the products that the robot will be palletizing? This will help you determine the robot’s reach and end effector.

- What is the weight of the products? This will help you determine the robot’s payload.

- What throughput do you require? This will help you determine the type of robot.

- How changeable are the product lines? This will determine how often you need to reprogram the robot.

- Do you need to be able to program the robot easily? If so, picking the right robot programming software is vital.

- Will you only be using the robot for palletizing or do you want it for other purposes? This will help you determine the type of robot.

Once you have identified the type of robot and your required specifications, take a look in our Robot Library at the different models that suit your needs. This will help you to quickly narrow down the choices to one or two robots.

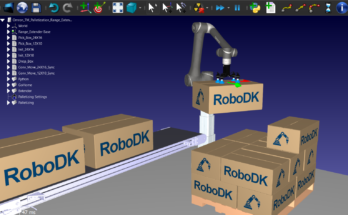

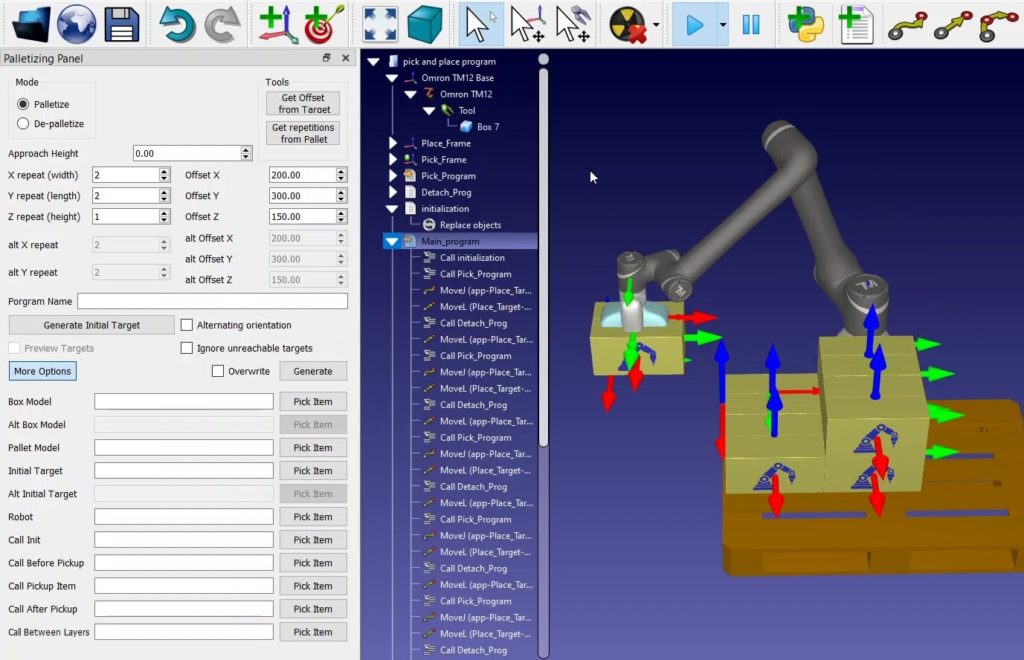

You can also use RoboDK’s robot palletizing plugin to simulate and generate programs with just a few clicks.

Which robot model looks like it’s the best for your needs? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.