Do you want to improve the speed of your pipe milling operations? Sure, automation is a good option… but, you might wonder, aren’t robots complex and don’t they take up a lot of space?

In this case study, we look at how one long-time RoboDK user has created an ingenious, commercial pipe milling solution. It’s completely self-contained and all fit inside a shipping container!

Like many manufacturing sectors, pipe milling is a growing market. But with increasing demand for pipe milling comes a problem…

How can you perform more milling operations when your production processes are already maxed out?

When Your Pipe Milling Operations Are Too Slow

The problem many manufacturers face is that their pipe milling processes are too slow. Conventional CNC machines require a lot of time to cut and mill large tubes and pipes.

This slow speed becomes even more problematic when you need to mill large pipes (an operation that is set to increase in demand by 140% by 2026). Often it involves doing several smaller milling operations and resetting the machines between each one, which is very time-consuming.

Robots are an excellent solution for milling large pipes and tubes. They have a huge workspace and you can apply them to a wider range of milling processes. This makes robot milling a good solution over conventional CNC processes.

Robot milling solutions work fine for all sizes of soft metal pipes (copper, aluminum, etc), small wall-thickness steel pipes, and all-size plastic pipes. Steel pipes of 0.08in or bigger wall thickness are still mostly cut using plasma, waterjet or laser connected to a robot arm. Robots can easily mill and cut pipes up to diam 40in and with a rotation table positioner easily 80in pipes.

Space and Complexity: The Challenges of Using Robots

What stops some manufacturers from using robots is the perceived complexity of deploying them and the extra space the robots require.

As well as purchasing the robot itself, you also need to source all the extra components needed to perform the milling task. Then, you need to find enough space in your facility to house the robot and these components, along with all the safety fencing and sensors.

Wouldn’t it be great if you could just buy a self-contained robot cell that includes everything you need for pipe milling?

(Re)introducing Sunrob Robotics…

Sunrob Robotics is a provider of advanced robotic applications. Based in Finland, they specialize in robotic pipe milling solutions. They also offer a range of other robotic solutions including packaging and 3D printing.

We previously reported on the team’s use of RoboDK for an agile tube-cutting solution for their clients, and their milling solution for custom ice hockey sticks.

With their latest project, Sunrob Robotics seeks to meet the rising need for more self-contained robotic cells. Using RoboDK, they have created a pipe milling solution… that fits in a shipping container!

Sunrob’s Pipe Milling Solution in a Container

The concept behind Sunrob’s pipe milling solution is that you can deploy it to your facility as a single, self-contained unit. It comes as a ready-to-use application for a completely customized pipe manufacturing process.

The robot and all the required components come pre-installed in a standard shipping container.

You don’t need to worry about how much space the robot and its associated components will take up in your facility — you just save enough space for one container and you know that will be enough.

Using a shipping container also removes the need to purchase and install safety fencing around the robot — you simply close the side of the container (which Sunrob has replaced with a roll door) and the robot can operate safely. And it means that the robot cell can be used outdoors or indoors, to suit your needs.

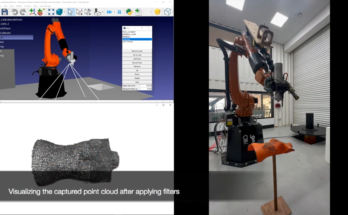

The Hardware Setup

The robot cell is based around the following hardware components:

- A standard-sized 20 or 40-foot shipping container.

- A KUKA 6 DoF industrial robot manipulator.

- KUKA positioners to rotate the pipe and move the robot.

- An HSD milling spindle with an automatic tool change feature or laser cutting or plasma cutting equipment.

The Software Setup

The core software components of the pipe milling cell are:

- RoboDK for robot programming.

- A CAD/CAM program to generate the machining paths.

- The RoboDK plugin to link the CAM program to the robot.

For example, some of Sunrob’s clients use Fusion 360 to create their machining paths. They then use the RoboDK Fusion 360 plugin to send these machining paths to the robot via RoboDK.

Speed Up Your Pipe Milling by 20%

What are the benefits of using a pipe milling solution like Sunrob’s?

One huge benefit is that improves the speed of your pipe milling operation. This allows you to mill more pipes faster, helping you to keep up with rising demand and make better use of your other machining processes.

One of Sunrob’s clients, RoadPipe Inc in Finland, used an earlier version of this pipe milling solution and found it to be extremely effective.

Rainer Jurvanen, CEO of RoadPipe, said:

“We should have bought our first robot 10 years ago! This robotic milling system is approximately 20 times faster than conventional manual manufacturing.”

This is a very common sentiment from new robot users. They realize how much time, effort, and resources they could have saved by simply choosing to use robots sooner.

If you haven’t started pipe milling yet, now is a good time to seriously consider it. There’s little benefit to be found from waiting to add robots to your production.

How to Improve Your Pipe Milling Tasks

If you are looking to improve your pipe milling tasks, a solution like this one from Sunrob Robotics can be a great option. You can find out more about this specific solution on their website.

And if you would like to improve your own robot milling process, a good place to start is to get familiar with RoboDK. With our highly popular robot programming software, you can easily program a huge range of manufacturing processes, including milling and other robot machining tasks.

What could you achieve with a robot pipe milling solution? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel