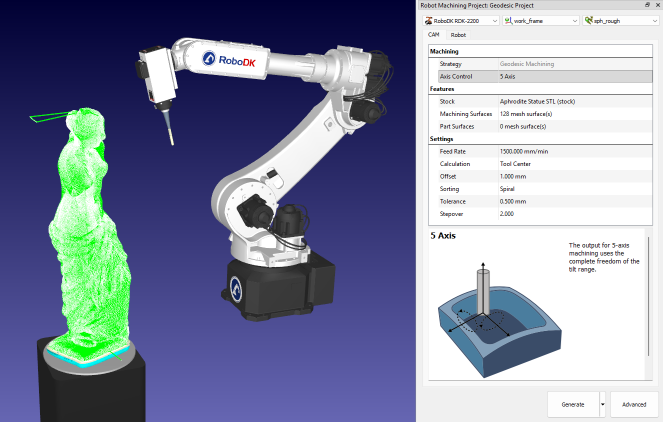

RoboDK CAM

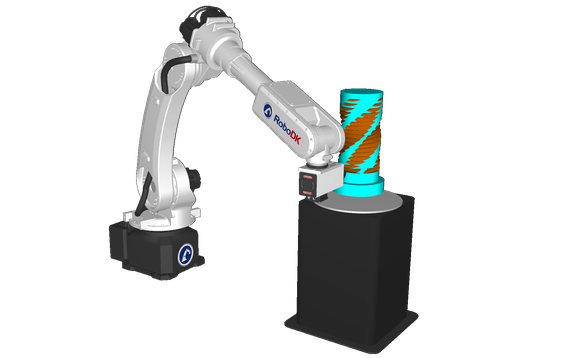

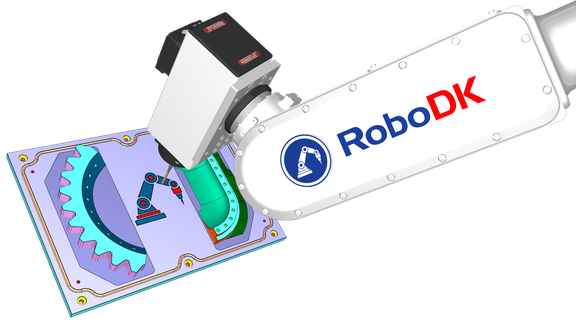

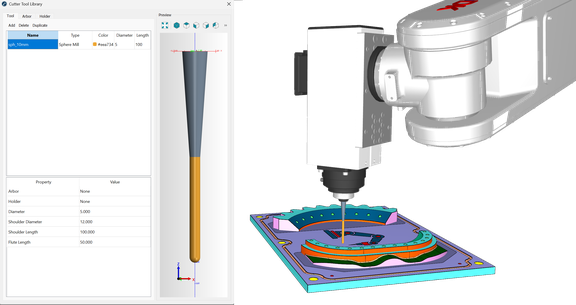

RoboDK CAM is robot programming software for CAM manufacturing.

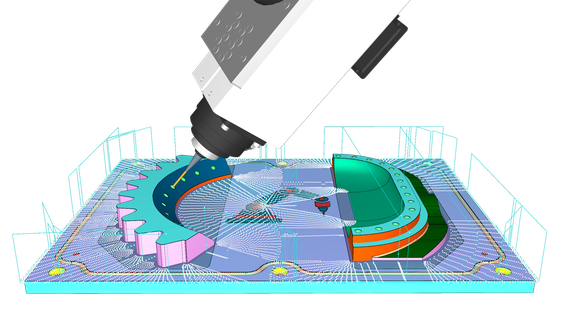

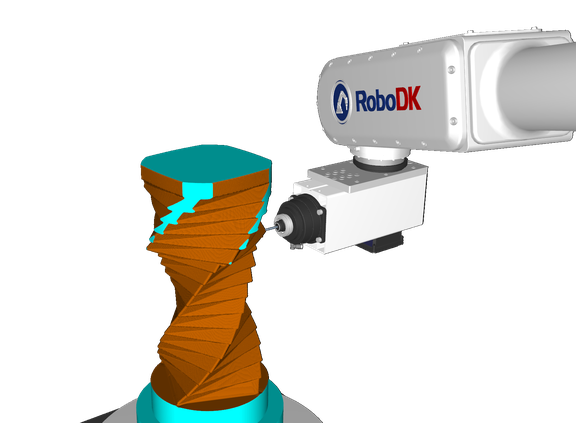

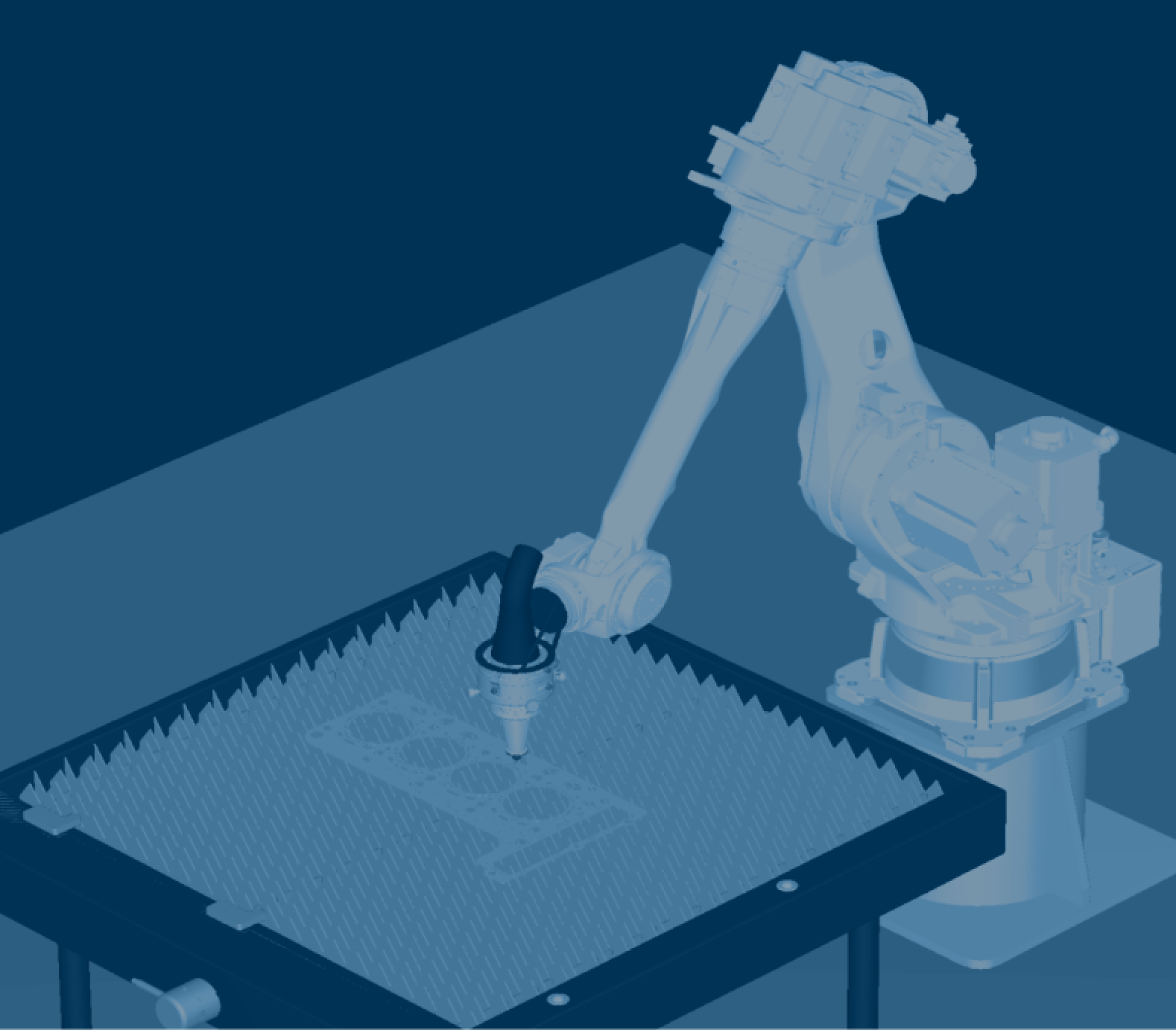

Computer Aided Manufacturing (CAM) software defines the trajectories (toolpath) that a robot or a CNC (Computer Numerical Control machinery) should follow to perform a manufacturing operation.